Features of Elastic Bearing

Strong Vertical Bearing Capacity: Elastic bearings from Tiantie are designed to support substantial vertical loads, ensuring structural stability.

Low Friction Coefficient: Tiantie's elastic bearings have a low friction coefficient, which minimizes resistance and enhances the efficiency of load transfer.

Unrestricted Horizontal Displacement: The horizontal displacement of our elastic bearings is not limited by the rubber materials, allowing for greater flexibility and movement within the structure.

Application of Elastic Bearing

As a common type of seismic isolators, the elastic bearing is widely used in the seismic isolation design and seismic reinforcement renovation of bridges, buildings, hydropower projects, house seismic facilities and other civil structures.

Why Choose Tiantie Elastomeric Bearings for Your Project?

Tiantie Elastomeric Bearings are the ideal choice for your project due to their exceptional characteristics. With a strong vertical bearing capacity, they provide reliable support for vertical loads. Their low friction coefficient minimizes resistance, ensuring smooth movement. Additionally, the ability for horizontal displacement, unrestricted by rubber materials, offers versatility in structural design. These advantages make Tiantie Elastomeric Bearings the preferred option for projects requiring robust support, minimal friction, and flexibility in structural movement.

How Elastomeric Bearings are Maintained?

Seismic isolation bearings in buildings require regular maintenance to ensure their effectiveness. Maintenance involves monitoring for changes, cleaning to remove debris, lubricating for smooth movement, and replacement when necessary. Adherence to manufacturer's guidelines and employing qualified engineers or contractors is crucial for maintaining the building's seismic base isolation system. Regular maintenance can help prevent potential issues and ensure the building remains safe and resilient in the event of an earthquake.

What is the Lifespan of Elastomeric Bearings?

The lifespan of elastomeric bearings, particularly those used in building seismic isolation, depends on various factors. These elastomeric bearings are crucial for accommodating movements and loads in infrastructure projects. The service life of elastomeric bearings is influenced by factors such as material quality and environmental conditions. High-quality elastomers like neoprene or natural rubber, known for their durability and resistance to weathering and chemicals, are commonly used to ensure longevity. Additionally, the operating environment significantly impacts the service life, with temperature fluctuations, UV exposure, moisture, chemical exposure, and ozone levels affecting the performance and deterioration of the elastomeric material over time. It is essential to consider these factors to ensure the effective and long-lasting performance of elastomeric bearings in building seismic isolation applications.

Natural Rubber Bearing

Natural Rubber Bearing

Lead Rubber Bearing

Lead Rubber Bearing

High Damping Rubber Bearing

High Damping Rubber Bearing

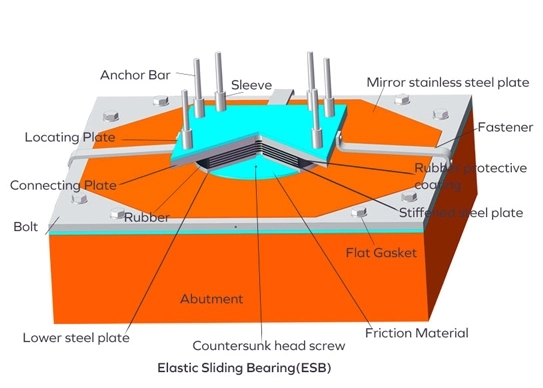

Elastic Bearing

Elastic Bearing

Friction Pendulum Seismic Isolation

Friction Pendulum Seismic Isolation

Simple Support For Village And Town Houses

Simple Support For Village And Town Houses